Electric Over Head Crane

Electric Over Head Crane Specification

- Power Source

- Electric

- Surface Finish

- Paint Coated

- Thickness

- Standard as per design

- Material

- Mild Steel

- Type

- Double Girder Electric Overhead Crane

- Structure

- Box Type

- Belt Conveyor

- Not Included

- Roller Conveyor

- Not Included

- Resistant Feature

- Corrosion Resistant

- Load Capacity

- 10 Ton

- Voltage

- 415 V

- Power

- 12 kW

- Usage & Applications

- Material handling in factories, warehouses, workshops, and industrial sheds

About Electric Over Head Crane

Our range of products includes Electric Over Head Crane that is quite popular in the market. These units are basically used at various construction sites for lifting and transporting heavy boulders from one to another. Manufactured from high quality raw material, these products exhibit smooth and trouble free operation, long service life, less maintenance and robustness. In order to maintain consistent quality, we conduct various tests on these products before it is delivered to the clients. Keeping in mind the various requirements of the clients, we alter the dimensions of these products. Electric Over Head Crane is available with us at industry leading rates.The Electric Over Head Crane is an essential tool for any industrial operation, providing a reliable and durable lifting solution. This crane has a wide range of applications, from moving heavy objects, steel and machinery to other operations such as construction and maintenance. Its durable components are designed to last for extended operating cycles, with easy maintenance and no external force needed for its operation. Its user-friendly design and ergonomics allow for simple, speedy and efficient operations, to maximize productivity and minimize downtime.

Features:

-

Smooth and easy to operate

-

Long Service Life

-

Available in varying capacities

Versatile Control Options

Choose from pendant, remote, or cabin control methods to suit specific operational needs and workplace safety standards. Whether you require hands-on guidance or remote accessibility, this crane adapts to your workflow, enhancing productivity and operator comfort.

Robust Construction & Performance

Constructed with a box-type double girder structure and forged steel wheels, the crane offers exceptional durability. Its heavy-duty, sealed bearings, wire rope hoist, and 415V electric operation deliver reliable lifting up to 10 tons, ensuring seamless handling of heavy materials in demanding environments.

Wide Span and Lifting Height

Designed for broad usage, the crane accommodates spans up to 30 meters and lifting heights up to 20 meters. This flexibility enables the efficient transport and loading of large or cumbersome items, making it ideal for extensive factory floors and warehouse setups.

FAQs of Electric Over Head Crane:

Q: How does the control method affect crane operation?

A: This electric overhead crane offers pendant, remote, and cabin controls, allowing operators to select the most suitable and safe option for their work environment. Each method provides varying degrees of proximity and oversight, which helps enhance workflow efficiency and safety.Q: What are the primary benefits of using a double girder structure?

A: A double girder structure ensures higher load capacities, greater span coverage, and improved structural stability. This makes it ideal for lifting heavy loads across wide areas, increasing both operational flexibility and safety.Q: When should I opt for Class II, III, or IV crane duty classifications?

A: Crane duty class determines suitability for the intensity of use: Class II is recommended for light to moderate use, Class III for frequent service, and Class IV for heavy-duty, continuous lifting operations in industrial environments.Q: Where is this electric overhead crane ideally used?

A: This crane is primarily installed in factories, industrial sheds, warehouses, and workshops. Its robust design and resistance to corrosion make it suitable for demanding material handling tasks in varied industrial settings throughout India.Q: What is the process for maintaining the cranes longevity?

A: Regular inspections, timely servicing of bearings and hoist mechanisms, and adherence to manufacturer guidelines are essential. Applying appropriate surface coatings and checking the integrity of forged wheels and wire ropes help ensure consistent performance and durability.Q: How does the wire rope hoist mechanism contribute to operational efficiency?

A: The wire rope hoist provides stability, high lifting capacity, and precise load handling. Its reliable performance results in smooth lifting and lowering operations, reducing downtime and improving workflow productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in E.O.T Cranes/ Hoists/CPB Category

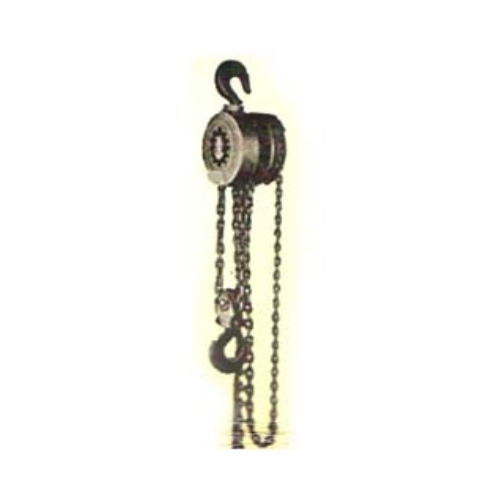

Chain Pulley Block

Voltage : Manual Operation (No Voltage Required)

Load Capacity : 1 Ton to 10 Ton

Power : Manual

Power Source : Manual

Usage & Applications : Lifting and lowering heavy loads in workshops, warehouses, factories, construction sites.

Speed : Depends on operator

Gantry Crane

Voltage : 415 V

Load Capacity : 5 Ton

Power : 7.5 kW

Power Source : Electric

Usage & Applications : Loading, unloading and material handling in open warehouse or construction sites

Speed : Travel Speed up to 20 m/min

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry