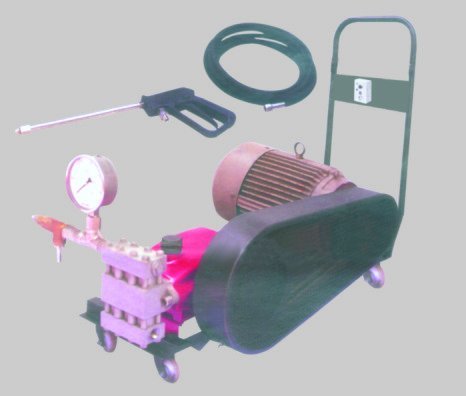

Motorised Hydraulic Testing unit

Motorised Hydraulic Testing unit Specification

- Accessories

- Pressure Gauge, Safety Valve, High Pressure Hose, Test Adaptors

- Power Source

- Electric Motor Driven

- Equipment Type

- Testing Unit

- Features

- Heavy duty construction, Pressure gauge, Safety valve, Mobility wheels, Leak proof testing.

- Connectivity Type

- Manual hydraulic coupling

- Material

- Mild Steel

- Type

- Motorised Hydraulic Testing Unit

- Condition

- New

- Fuel Type

- Electric

- Use

- Hydraulic Pressure Testing of Pipes, Cylinders, Valves, Vessels etc.

- Cleaning Type

- Hydraulic Pressure Testing

- Capacity

- Up to 700 bar (as per model)

- Voltage

- 230V / 415V, 50 Hz

About Motorised Hydraulic Testing unit

Motorised Hydraulic Testing unit

We are eminent manufacturer and supplier of high grade range of Motorized Hydraulic Testing Unit. We are acclaimed for consistency in quality delivered as we monitor the quality of the product we manufacture. This material handling equipment manufactured by us is impeccably featured with high-performance motor for uninterrupted motion, adjustable pressure gauge to control the pressure and castor wheels for mobility. Our Motorized Hydraulic Testing Unit operates very easily meeting the requirement to be ultra quiet for test lab use and deliver accurate results. These units are quite common in use for hydraulic testing of boiler, fabrication of vessels and cleaning of boiler tubes. We offer this product to at the most reasonable prices in order to meet the budgetary requirements of our clients.

Features:

- High performance

- Portable

- Accuracy in results

- Economical

Advanced Hydraulic Testing Solution

This motorised hydraulic testing unit is engineered to deliver accurate hydraulic pressure testing for various components, including pipes, cylinders, and valves. With testing capacities up to 700 bar and options for 1.0 HP to 3.0 HP electric motors, the equipment combines efficiency and safety. Industrial powder-coated mild steel construction enhances longevity, while the mobile design provides convenient relocation across sites.

Built for Safety, Mobility, and Ease of Use

Integrated safety relief valves, pressure gauges, and high-pressure hoses ensure safe and accurate testing operations. The units mobility wheels make it easy to maneuver, and its low noise level supports a comfortable working environment. Compatibility with different liquids allows for adaptable use, and manual hydraulic couplings simplify connection to the test subject. Supplied accessories cover all standard testing requirements.

FAQs of Motorised Hydraulic Testing unit:

Q: How is the motorised hydraulic testing unit typically used?

A: The unit is used for hydraulic pressure testing of pipes, cylinders, valves, and vessels to assess their durability and leak-resistance. Simply connect the component to be tested using the included high-pressure hose and adaptors, select an appropriate test medium, and operate the unit as per the manual to build and monitor pressure.Q: What are the main benefits of using this hydraulic testing unit?

A: Key benefits include heavy-duty construction for durability, portability due to mounted wheels, efficient pressure generation up to 700 bar, and reliable safety features like the integrated safety relief valve. Its low noise operation and comprehensive accessories streamline the testing process.Q: When should I use water or oil as the test medium?

A: The choice of test medium depends on the compatibility with the material being tested and the type of system. Water is commonly used for general applications, while oil or other compatible liquids may be preferred for systems sensitive to corrosion or where water cannot be used.Q: Where can the hydraulic testing unit be deployed?

A: This testing unit is suitable for use in industrial workshops, pipe fabrication yards, valve manufacturing plants, and inspection sites. Its wheeled design allows easy transport across different locations or within large facilities.Q: What safety mechanisms are integrated into the unit?

A: The unit features a built-in safety relief valve that prevents over-pressurization, a pressure gauge for real-time monitoring, and leak-proof construction to ensure safe and reliable operation throughout the testing process.Q: How do I connect the component to be tested with this unit?

A: The unit is equipped with a manual hydraulic coupling system and comes with various test adaptors, allowing straightforward and secure connection to pipes, cylinders, or vessels before commencing the pressure test.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in High Pressure Jet Cleaning Machine Category

Presssure Jet Cleaning Machine

Minimum Order Quantity : 1 Unit

Cleaning Type : Other, Surface Cleaning

Condition : New

Fuel Type : Electric

Material : Other, Stainless Steel

Use : Other, Industrial Cleaning

High Pressure Jet Cleaning Machine

Cleaning Type : Other, Surface and Equipment Cleaning

Condition : New

Fuel Type : Electric

Material : Other, Mild Steel Body

Use : Other, Industrial and Commercial Cleaning

Jet Cleaning

Minimum Order Quantity : 1 Unit

Cleaning Type : High Pressure Cleaner

Condition : New

Fuel Type : Electric

Material : Metal

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry