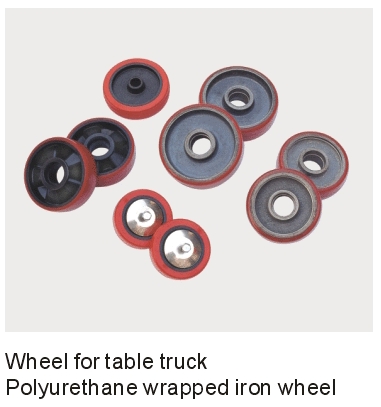

PU CI Bonded Wheel

PU CI Bonded Wheel Specification

- Rotation Type

- 360 Swivel or Fixed (as required)

- Control System

- Manual

- Equipment Type

- Material Handling Wheel

- Forklift

- Compatible with forklifts, pallet trucks, trolleys

- Wheel Type

- PU Bonded on CI (Cast Iron)

- Condition

- New

- Lifting Capacity

- Up to 2000 kg (varies by size)

- Max. Lifting Load

- 2000 kg

About PU CI Bonded Wheel

PU CI Bonded Wheel

We have in store for our clients PU CI Bonded Wheel. Polyurethane with high abrasion resistance bonded (molded), over a cast iron core forms a PU-CI wheels. The properties of cast polyurethane are much better than that of injection molded polyurethane. Our clients prefer our products owing to its heavy load carrying capacity, long life of the wheel, good shock absorbing capacity and very low level of noise.

Features:

- Heavy load carrying capacity

- Durable

- Good shock absorbing capacity

- Low level of noise

Superior Load Capacity

Engineered to support up to 2000 kg depending on wheel size, the PU CI Bonded Wheel ensures efficient and safe movement of heavy materials. Its robust construction allows for dependable usage in warehouses, factories, and other industrial settings where weight-bearing capabilities are crucial.

Optimized for Industrial Environments

The combination of polyurethane tread and cast iron core makes this wheel ideal for harsh working conditions. Resistant to oils, greases, mild acids, and alkalis, it excels in industrial operations where chemical exposure is common and durability is paramount.

FAQs of PU CI Bonded Wheel:

Q: How do I select the correct PU CI Bonded Wheel size for my material handling equipment?

A: Choose your wheel diameter and width based on equipment specifications and load requirements. Available sizes range from 100 to 400 mm in diameter and 50 to 100 mm in width. Consider the type of mounting (plain bore, ball bearing, or roller bearing) and required lifting capacity for best results.Q: What are the main benefits of using a polyurethane tread with a cast iron core?

A: Polyurethane treads offer excellent wear resistance, chemical resilience, and vibration absorption. When bonded to a cast iron core, the wheel achieves exceptional strength, stability, and durability for heavy-duty applications, ideal for forklifts, trolleys, and automated machinery.Q: Where can PU CI Bonded Wheels be applied?

A: These wheels are widely used in material handling equipment such as pallet trucks, industrial trolleys, automated machinery, and are compatible with forklifts in warehouses, manufacturing plants, distribution centers, and other commercial facilities.Q: What is the recommended process for installing PU CI Bonded Wheels?

A: Installation depends on the specific mounting type. For plain bore wheels, slide onto the axle, while ball bearing or roller bearing models require appropriate fitting into the designated brackets. Always adhere to equipment manual guidelines to ensure safety and optimal performance.Q: Can I customize the colour and specifications of these wheels for my application?

A: Yes, while yellow is the standard colour, custom hues and sizes can be requested to match branding or operational requirements. Discuss your needs with the manufacturer, distributor, or supplier for tailored solutions.Q: When should the wheels be replaced to ensure reliability and safety?

A: Regularly inspect wheels for signs of tread wear, damage, or loss of chemical resistance. Replace immediately if the wheel shows cracks, reduced lifting capacity, or compromised rotation, to maintain safe material handling operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Wheel and Casters Category

RG with Brake RG with Brake

Minimum Order Quantity : 50 Units

Condition : New

Equipment Type : Industrial Lifting Equipment

Features : Safety Interlock, High Strength

Wheel Type : Other, Polyurethane/Cast Iron

Attributes : Other, Heavy Duty, Corrosion Resistant

Flange Track

Minimum Order Quantity : 50 Units

Condition : New

Equipment Type : Other Equipment, Industrial Track

Features : Effortless Sliding, High Load Endurance

Wheel Type : Other, Forged Steel

Attributes : Other, Corrosion Resistant, Durable Finish Standard

Cast Iron (SQG) Wheel

Minimum Order Quantity : 50 Units

Condition : New

Equipment Type : Material Handling Wheel

Features : Shock and Abrasion Resistant

Wheel Type : Other, Cast Iron (SQG)

Attributes : Other, High Strength, Durable, Wear Resistant

Polyurethane Bonded Cast Iron Wheel

Minimum Order Quantity : 10 Units

Condition : New

Equipment Type : Material Handling Wheel

Features : Abrasion Resistant, Long Life

Wheel Type : Other, Polyurethane Bonded on Cast Iron Core

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry