E.O.T Cranes / Hoists / CPB

E.O.T Cranes / Hoists / CPB Specification

- Wheel Type

- Forged Steel

- Equipment Type

- EOT Crane / Hoist / CPB

- Rotation Type

- Single or Double Girder

- Control System

- Pendant/Remote/Panel

- Belt Type

- Wire Rope or Chain

- Motor Type

- Squirrel Cage Induction Motor

- Handle Type

- Pendant Push Button, Wireless Remote

- Condition

- New

- Lifting Capacity

- 10 Ton

- Max. Lifting Load

- 10 Ton

- Max. Lifting Height

- 15 m

- Power Source

- Electric

- Power Consumption

- Variable (as per model)

- Voltage

- 380 V

- Length of Belt

- Customized as per requirement

- Attributes

- Heavy Duty, Durable

About E.O.T Cranes / Hoists / CPB

Optimized for Versatility and Safety

Our E.O.T Cranes, Hoists, and CPBs are crafted for a broad spectrum of applications, from assembly lines to heavy foundry tasks. The equipment features a safety yellow finish for enhanced visibility, with color customization available to meet site-specific safety protocols. The high-quality electric hoists ensure efficient, safe material handling, while heavy-duty forged steel wheels and a durable wire rope or chain belt maximize operational longevity.

Advanced Control and Precision Handling

Each system offers flexible control options, including pendant push button, wireless remote, or panel-based systems. This allows operators to choose the most convenient and safe handling method. The combination of variable power consumption, precise electric control, and squirrel cage induction motors results in reliable, low-maintenance operation, enabling smooth and precise load movements even under demanding conditions.

FAQs of E.O.T Cranes / Hoists / CPB:

Q: How are E.O.T cranes and hoists installed on-site?

A: E.O.T cranes and hoists are usually installed by certified professionals. The process includes site assessment, assembling the single or double girder structure, mounting the forged steel wheels, setting up electric hoists, and configuring control systems. Customizations, such as lifting height and belt length, are incorporated per project requirements.Q: What environments are suitable for using these cranes and hoists?

A: These cranes and hoists are ideal for use in factories, warehouses, assembly lines, and foundries, thanks to their robust construction, safety features, and compliance with IS 3177/IS 807 standards. Heavy duty capacity and durable components make them well-suited to industrial and commercial settings.Q: When should I consider automated control versus manual control for these cranes?

A: Automated control systems, like wireless remotes or control panels, are recommended for high-frequency or long-span operations where operator safety and efficiency are paramount. Manual controls, such as pendant push buttons, are suitable for lower-frequency or more localized lifting tasks.Q: Where is the equipment typically used within an industrial setup?

A: These E.O.T cranes and hoists are commonly positioned over workstations, production lines, storage areas, or foundry bays to facilitate the lifting and transport of heavy goods throughout the facility.Q: What is the benefit of the adjustable lifting height and belt length?

A: Adjustable lifting height and customizable belt length provide flexibility to match unique site conditions and material handling needs, ensuring efficient and safe operation for different load types and workspace arrangements.Q: How does the power source and voltage specification affect crane usage?

A: With 380 V electric power and variable power consumption tailored to each model, these cranes deliver reliable performance in industrial environments, ensuring adequate lifting power while maintaining energy efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in All Type of Hydraulic Stacker Category

Fully Battery Operated Stacker

Minimum Order Quantity : 1 Unit

Power Source : Battery Operated

Max. Lifting Load : 1000 kg

Rotation Type : 180 Degree Steering

Condition : New

Attributes : Other, Heavy Duty, Robust Design

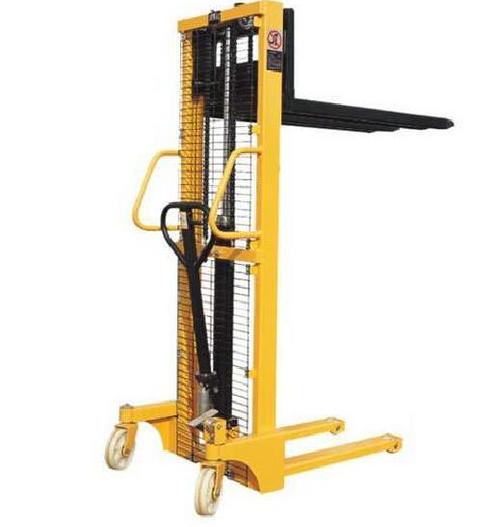

Manual Stacker

Power Source : Manual

Max. Lifting Load : 1000 kg

Rotation Type : Fixed Mast

Condition : New

Attributes : Other, Manual, Hydraulic Lifting

Drum Trolley

Minimum Order Quantity : 1 Unit

Power Source : Manual

Max. Lifting Load : 300 Kg

Rotation Type : Tilting / Drum Rotating Feature

Condition : New

Attributes : Other, Heavy Duty, Corrosion Resistant

Mast Aerial Platform

Minimum Order Quantity : 1 Unit

Power Source : Electric

Max. Lifting Load : 200 kg

Rotation Type : Fixed Vertical Lift

Condition : New

Attributes : Other, Lightweight, Compact Design

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry