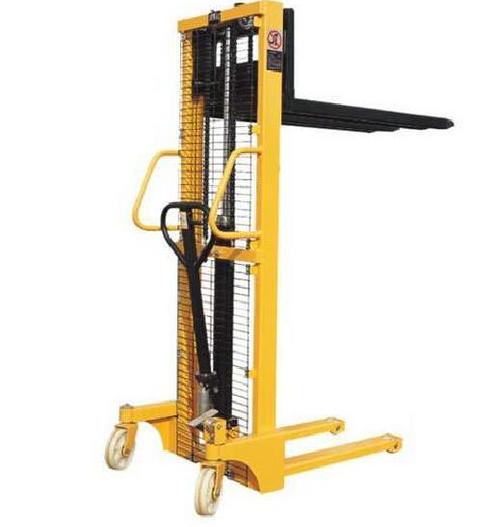

Manual Stacker

Manual Stacker Specification

- Lifting Speed

- Manual (dependent on operator)

- Rotation Type

- Fixed Mast

- Forklift

- No

- Wheel Type

- Nylon/Castor Wheels

- Features

- Compact Design, Easy Maneuvering

- Handle Type

- Push/Pull Ergonomic Handle

- Control System

- Manual Pump

- Equipment Type

- Manual Stacker

- Rack Capacity

- 1000 kg

- Condition

- New

- Lifting Capacity

- 1000 kg

- Max. Lifting Load

- 1000 kg

- Max. Lifting Height

- 1600 mm

- Power Source

- Manual

- Power Consumption

- Manual Operation

- Feature

- Easy Handling, Durable Wheels, Robust Construction

- Attributes

- Manual, Hydraulic Lifting

- Surface Finish

- Powder Coated

- Net Weight

- 130 kg

- Fork Length

- 1150 mm

- Number of Wheels

- 4

- Ground Clearance

- 85 mm

- Material

- High Grade Steel

- Fork Width

- 550 mm

- Height Adjustment Mechanism

- Hydraulic Pump

- Travel Speed

- Manual

- Usage

- Warehouse, Material Handling

- Wheel Material

- Polyurethane

- Application

- Pallet Lifting, Stacking

- Colour

- Safety Yellow

About Manual Stacker

Manual Stacker

| Item/ Type | SFH 10 | SFH 15 | SHFD 10 | |

|---|---|---|---|---|

| Capacity Q | Kg | 1000 | 1500 | 1000 |

| Min fork height h | mm | 85 | 85 | 85 |

| Min mast height h1 | mm | 1600 | 1600 | 2500 |

| Min mast height h1 | mm | 1980 | 1980 | 1830 |

| Size of fork e*s | mm | 150/160x60 | 150/160x60 | 150/160x60 |

| Length of fork | mm | 900/1150 | 900/1150 | 900/1150 |

| Width of overall fork (adjust/fixed)b5 | mm | 330~740/550 | 330~740/550 | 330~740/550 |

| Radius of gyration | mm | 1250/1380 | 1250 | 1250/1000 |

| Weight | kg | 240/220 | 260 | 300 |

| Fork rollers | mm | 74 x 70 | 74 x 70 | 74 x 70 |

| Big wheel | mm | 180 x 50 | 180 x 50 | 180 x 50 |

Robust Construction for Demanding Warehouses

Built from high-grade steel and featuring a robust powder-coated surface, this manual stacker promises strength and longevity. It is crafted to deliver reliable performance in heavy-duty warehouse operations, ensuring high lifting capacity with minimal maintenance. Its ergonomic and compact design enables operators to maneuver goods safely even in compact environments.

Effortless Lifting with Hydraulic Precision

The hydraulic pump mechanism enables precise height adjustments, lifting loads up to 1000 kg to a maximum height of 1600 mm. Operators enjoy manual control, and the stackers smooth hydraulic system makes pallet stacking and handling less physically demanding, bolstering workplace efficiency without the need for external power.

FAQs of Manual Stacker:

Q: How does the height adjustment mechanism of the manual stacker work?

A: The manual stacker uses a hydraulic pump for height adjustment, allowing operators to raise or lower the forks smoothly by manually operating the hydraulic handle. This mechanism provides precise control over lifting up to 1600 mm.Q: What are the main applications of this manual stacker in a warehouse setting?

A: This manual stacker is primarily used for pallet lifting, stacking, and general material handling tasks. Its compact design and ergonomic handle make it suitable for navigating tight warehouse aisles and lifting heavy loads efficiently.Q: When should I consider using a manual stacker over an electric or forklift model?

A: A manual stacker is ideal when you need to move moderate loads (up to 1000 kg) without access to external power sources or where space is limited. Its perfect for warehouses with light to medium stacking demands and scenarios prioritizing cost-efficiency and simplicity.Q: Where can this stacker be operated most effectively?

A: The manual stacker is best suited for indoor environments like warehouses, production facilities, and storage units. Its polyurethane wheels and safety yellow color enhance safety and maneuverability on smooth industrial floors.Q: What is the process for regular maintenance of the manual stacker?

A: Regular maintenance involves inspecting the hydraulic pump for leaks, checking wheel integrity, ensuring bolts are tight, and keeping the surface clean. Minimal lubrication and routine cleaning extend its lifespan and maintain optimal performance.Q: How does manual operation benefit material handling tasks?

A: Manual operation reduces dependency on electricity, keeps operational costs low, and allows precise control during lifting and stacking. This type of stacker is reliable, requires little training, and is less susceptible to mechanical breakdowns compared to powered alternatives.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in All Type of Hydraulic Stacker Category

E.O.T Cranes / Hoists / CPB

Minimum Order Quantity : 1 Unit

Control System : Pendant/Remote/Panel

Condition : New

Attributes : Other, Heavy Duty, Durable

Max. Lifting Load : 10 Ton

Equipment Type : EOT Crane / Hoist / CPB

Forklift Series

Minimum Order Quantity : 1 Unit

Control System : AC Motor Controller

Condition : New

Attributes : Other, High Strength, Durable

Max. Lifting Load : Up to 5 Tons

Equipment Type : Other Equipment, Counterbalance / Reach Type

Mast Aerial Platform

Minimum Order Quantity : 1 Unit

Control System : Push Button/Platform Control Panel

Condition : New

Attributes : Other, Lightweight, Compact Design

Max. Lifting Load : 200 kg

Hydraulic Semi Electric Stacker

Control System : Semi Electric

Condition : New

Attributes : Other, Easy to Operate, Heavy Duty Construction

Max. Lifting Load : 2000 Kg

Equipment Type : Other Equipment, Material Handling Equipment

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry