Forklift Series

Forklift Series Specification

- Rack Capacity

- Customizable

- Lifting Speed

- 180 mm/sec

- Wheel Type

- Solid Rubber / Polyurethane

- Control System

- AC Motor Controller

- Rotation Type

- 360 Degree Maneuverability

- Forklift

- Electric / Diesel Options

- Features

- Easy Servicing, High Visibility Cabin

- Motor Type

- AC Electric Motor

- Equipment Type

- Counterbalance / Reach Type

- Condition

- New

- Max. Lifting Load

- Up to 5 Tons

- Power Source

- Battery Operated

- Power Consumption

- Efficient Energy Usage

- Voltage

- 24V / 48V

- Attributes

- High Strength, Durable

About Forklift Series

Forklift series specifically designed and constructed to operate in limited spaces while still offering: Ease of handling, Reliability, Safety and high Productivity.

Highly Customizable Handling Equipment

This forklift series caters to a wide range of operational needs, offering customizable color options, fork configurations, power sources, and rack capacities. The high-strength frame and durable materials ensure long-term reliability, while the ergonomic, high-visibility cabin enhances safety and comfort for operators. Whether used indoors or outdoors, these forklifts guarantee optimal performance under varying conditions.

Efficient and Eco-Friendly Performance

With efficient energy consumption, advanced AC motor controllers, and low noise output, these forklifts not only reduce operational costs but also improve and maintain a quieter, eco-conscious workplace. The regenerative braking system further contributes to energy conservation, making them a smart investment for sustainability-focused businesses.

FAQs of Forklift Series:

Q: How does the regenerative braking system enhance operational efficiency in these forklifts?

A: The regenerative braking system converts the kinetic energy generated during braking into electrical energy, which is redirected to recharge the battery. This process increases energy efficiency, extends battery life, and reduces overall power consumption during daily operations.Q: What makes these forklifts suitable for both indoor and outdoor applications?

A: Equipped with either pneumatic or solid tires and offering various driving and operation modes, these forklifts are adaptable to multiple environments. Their robust construction, adjustable rack capacity, and flexibility in wheel type (solid rubber or polyurethane) ensure reliable performance on a variety of surfaces.Q: Where can these forklifts be utilized most effectively?

A: They are particularly effective in warehouses, manufacturing plants, distribution centers, and storage facilities. The combination of high lifting capacities, customizable features, and quiet operation makes them a reliable choice for industries across India needing efficient material handling solutions.Q: What is the process for servicing these forklifts, and is maintenance straightforward?

A: These forklifts are engineered with easy servicing in mind. High accessibility to key components, advanced AC motor controllers, and durable design enable quick, hassle-free maintenance, reducing downtime and long-term operating costs for owners and operators.Q: When is it beneficial to choose automatic operation over manual operation?

A: Automatic operation is advantageous in high-throughput environments where ease of use, speed, and consistency are priorities. For more specialized or precise tasks, manual operation may offer greater control over maneuvering. The flexibility in operation mode allows you to match the forklift with your specific workflow requirements.Q: What are the main benefits of having a high-visibility cabin and power steering in these forklifts?

A: A high-visibility cabin improves operator awareness, reducing the risk of accidents, while power steering significantly eases maneuverability, especially in confined spaces. Together, these features increase safety and productivity during prolonged operation periods.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in All Type of Hydraulic Stacker Category

E.O.T Cranes / Hoists / CPB

Minimum Order Quantity : 1 Unit

Condition : New

Control System : Pendant/Remote/Panel

Attributes : Other, Heavy Duty, Durable

Lifting Capacity : 10 Ton

Handle Type : Pendant Push Button, Wireless Remote

Fully Battery Operated Stacker

Minimum Order Quantity : 1 Unit

Condition : New

Control System : Microprocessor Based

Attributes : Other, Heavy Duty, Robust Design

Lifting Capacity : 1000 kg

Handle Type : Ergonomic Rubber Grip

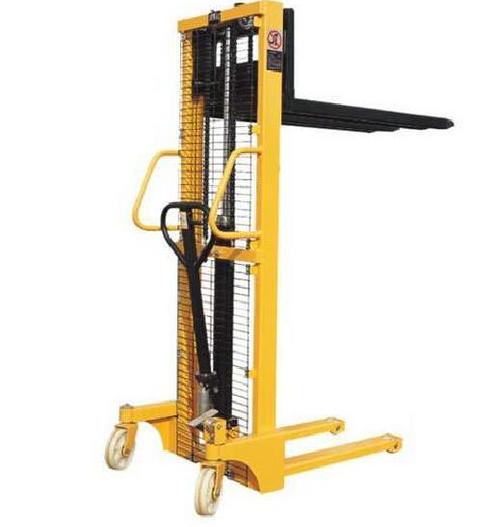

Manual Stacker

Condition : New

Control System : Manual Pump

Attributes : Other, Manual, Hydraulic Lifting

Lifting Capacity : 1000 kg

Handle Type : Push/Pull Ergonomic Handle

Drum Trolley

Minimum Order Quantity : 1 Unit

Condition : New

Control System : Manual

Attributes : Other, Heavy Duty, Corrosion Resistant

Lifting Capacity : 300 Kg

Handle Type : Ergonomic

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry