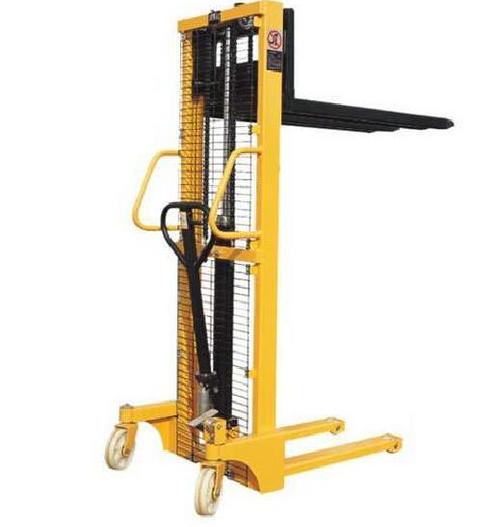

Fully Battery Operated Stacker

Fully Battery Operated Stacker Specification

- Lifting Speed

- 110 mm/sec

- Motor Type

- AC Drive Motor

- Handle Type

- Ergonomic Rubber Grip

- Control System

- Microprocessor Based

- Forklift

- No

- Equipment Type

- Warehouse Material Handling

- Rotation Type

- 180 Degree Steering

- Wheel Type

- PU (Polyurethane) Wheels

- Condition

- New

- Lifting Capacity

- 1000 kg

- Max. Lifting Load

- 1000 kg

- Max. Lifting Height

- 3000 mm

- Power Source

- Battery Operated

- Power Consumption

- 2.2 kW

- Voltage

- 24 V DC

- Attributes

- Heavy Duty, Robust Design

About Fully Battery Operated Stacker

| Identification | 1.2 | Manufacturer's type designtaion |

| CS1543 | CS1546 |

|---|---|---|---|---|---|

| 1.3 | Drive: electric (battery or mains), diesel, petrol, fuel gas, manual |

| Electric | Electric | |

| 1.4 | Type of operation: hand, pedestrian, standing, seated, order- picker |

| Pedestrian | Pedestrian | |

| 1.5 | Load Capacity/ rated load | Q (t) | 1.5 | 1.5 | |

| 1.6 | Load center distance | C mm | 600 | 600 | |

| 1.8 | Load distance, centre of drive axle to fork | X mm | 765 | 765 | |

| 1.9 | Wheelbase | Y mm | 1420 | 1420 | |

| Weights | 2.1 | Service Weight | Kg | 1273 | 1315 |

| 2.2 | Axle loading, laden front/ rear | Kg | 1345/1428 | 1360/1455 | |

| 2.3 | Axle loading, unloading front/rear | Kg | 946/324 | 970/345 | |

| Wheels Chassis | 3.1 | Tyres: solid rubber, superelastic, pneumatic, polyurethane) |

| Polyurethane | Polyurethane |

| 3.2 | Tyre size, front |

| 230 x 75 | 230 x 75 | |

| 3.3 | Tyre size. Rear |

| 80 x 70 (1) | 80 x 70 (1) | |

| 3.4 | Additional wheels (dimensions) |

| 124 x 60 | 124 x 60 | |

| 3.5 | Wheels, number front/ rear (x=driven wheels) |

| 1x+2/4 | 1x+2/4 | |

| 3.6 | Track width, front | B10 (mm) | 680 | 680 | |

| Basic Dimensions | 3.7 | Track width, rear | B11 (mm) | 395 | 395 |

| 4.2 | Lowered mast height | H1 (mm) | 1955 | 2105 | |

| 4.3 | Free lift | H2 (mm) | 1380 | 1505 | |

| 4.4 | Lift height | H3 (mm) | 4265 | 4515 | |

| 4.5 | Extended mast height | H4 (mm) | 4865 | 5115 | |

| 4.9 | Height of tilter in drive position min./ max | H14(mm) | 864/1287 | 865/1287 | |

| 4.15 | Lowered height | H13(mm) | 85 | 85 | |

| 4.19 | Overall length | L1 (mm) | 2065 | 2065 | |

| 4.20 | Length to face of forks | L2(mm) | 915 | 915 | |

| 4.21 | Overall width | B1 (mm) | 915 | 915 | |

| 4.22 | Fork dimensions | S/e/I(mm) | 60/180/1150 | 60/180/1150 | |

| 4.25 | Width over forks | B5 (mm) | 575 | 575 | |

| 4.32 | Ground clearance, center of wheelbase | M2(mm) | 25 | 25 | |

| 4.33 | Aisle width for pallets 1000 x 1200 crossways | Ast (mm) | 2354 | 2354 | |

| 4.34 | Aisle width for pallets 800 x 1200 lengthways | Ast (mm) | 2300 | 2300 | |

| 4.35 | Tuming radius | Wa (mm) | 1710 | 1710 | |

| Performance Data | 5.1 | Travel Speed, laden/unladen | Km/h | 5/5.5 | 5/5.5 |

| 5.2 | Lift speed, laden/unladen | Mm/s | 141/163 | 106/170 | |

| 5.3 | Lowering speed, laden/unladen | Mm/s | 96/80 | 96/80 | |

| 5.8 | Max gradient performance, laden/unladen | % | 6/12 | 6/12 | |

|

| 5.10 | Service brake |

| Electromagnetic | Electromagnetic |

| E- Motor | 6.1 | Drive motor rating s2 60min | Kw | 1.5 | 1.5 |

| 6.2 | Lift motor rating | Kw | 3 | 3 | |

| 6.3 | Battery acc to BS, no |

| 4VBS | 4VBS | |

| 6.4 | Battery voltage, norminal capacity | V/Ah | 24/280 | 24/280 | |

| Others | 8.1 | Type of drive control |

| MOSFET Control | MOSFET Control |

| 8.4 | Sound level at driver's ear acc. To EN12053 | dB(A) | 68 | 68 |

Heavy Duty Performance for Demanding Environments

This stacker is engineered to excel in busy warehouses and factories, offering a lifting capacity of 1000 kg and a robust, reliable construction. Its AC drive motor and ergonomic rubber-grip handle provide smooth yet powerful lifting and maneuvering, even in tight or crowded spaces. The dual/single mast configurations cater to variable stacking heights and operational needs.

Advanced Battery System for Extended Operation

Equipped with a 24V DC system powered by two high-capacity 12V/120Ah batteries, this fully battery operated stacker ensures long-lasting performance. The integrated automatic charger simplifies recharging, reducing downtime and keeping material handling operations running efficiently throughout the workday.

User-Centric Safety and Control Features

An electromagnetic braking system, adjustable lowering speed, and polyurethane wheels deliver superior control and safety. Microprocessor-based controls ensure precision handling, while the ergonomic handle enhances user comfort and productivity during extended use.

FAQs of Fully Battery Operated Stacker:

Q: How does the fully battery operated stacker benefit warehouse operations?

A: The stacker streamlines material handling by allowing quick stacking, loading, and unloading of pallets, thereby increasing productivity and reducing manual labor. Its robust battery system, ergonomic controls, and high lift capacity make it ideal for continuous use in professional environments.Q: What is the process for charging the stackers batteries?

A: Charging is straightforward thanks to the integrated automatic charger. Simply connect the stacker to a standard power outlet; the system manages the charging cycle, ensuring the batteries are safely replenished for optimal performance.Q: When should the stackers batteries typically be recharged?

A: The batteries should be recharged when the stacker indicates a low battery level, usually after a full day of operation or when performance starts to decline. Regular recharging after use maximizes battery life and keeps the machine ready for work.Q: Where can this stacker be effectively utilized?

A: This stacker is specifically designed for use in warehouses, factories, and distribution centers for pallet stacking, loading, and unloading tasks. Its compact design and 180-degree steering enable efficient operation in confined areas and aisles.Q: How is the load securely lifted and maneuvered?

A: The microprocessor-based control system, electromagnetic braking, and ergonomic handle allow precise lifting and safe transport of loads up to 1000 kg. The polyurethane wheels ensure stability and smooth movement across warehouse floors.Q: What maintenance is required for the stacker?

A: Regular checks of battery levels, wheel condition, and the braking system ensure longevity and safe performance. Clean the stacker periodically and follow the manufacturers maintenance schedule for motor, hydraulic, and control systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in All Type of Hydraulic Stacker Category

Manual Stacker

Control System : Manual Pump

Attributes : Other, Manual, Hydraulic Lifting

Condition : New

Max. Lifting Load : 1000 kg

Rotation Type : Fixed Mast

E.O.T Cranes / Hoists / CPB

Minimum Order Quantity : 1 Unit

Control System : Pendant/Remote/Panel

Attributes : Other, Heavy Duty, Durable

Condition : New

Max. Lifting Load : 10 Ton

Rotation Type : Single or Double Girder

Drum Trolley

Minimum Order Quantity : 1 Unit

Control System : Manual

Attributes : Other, Heavy Duty, Corrosion Resistant

Condition : New

Max. Lifting Load : 300 Kg

Rotation Type : Tilting / Drum Rotating Feature

Mast Aerial Platform

Minimum Order Quantity : 1 Unit

Control System : Push Button/Platform Control Panel

Attributes : Other, Lightweight, Compact Design

Condition : New

Max. Lifting Load : 200 kg

Rotation Type : Fixed Vertical Lift

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry